Powering the New Era of American Propulsion

In the competitive and strategically vital realm of aerospace and defense, where reliable and high-performance propulsion is paramount, Ursa Major has rapidly emerged as a foundational player. Founded in 2015 by former SpaceX and Blue Origin propulsion engineer Joe Laurienti, this Berthoud, Colorado-based company is redefining the landscape of rocket engine manufacturing. Ursa Major is not merely building engines; it is strengthening the U.S. defense industrial base and enabling a new generation of launch vehicles, hypersonics, and in-space capabilities by providing propulsion systems as a service, significantly reducing the cost and lead time traditionally associated with in-house development.

The Genesis of a New Model: Speed, Scale, and Specialization

Joe Laurienti founded Ursa Major with a clear vision: to specialize in rocket propulsion and provide reliable, high-performance engines to a market often constrained by long lead times and high development costs for in-house solutions. His experience at leading aerospace companies highlighted a critical bottleneck: propulsion is notoriously difficult, slow, and expensive to develop, and it’s the most common cause of launch failures. Ursa Major set out to address this by focusing on rapid iteration, advanced manufacturing techniques (particularly additive manufacturing), and rigorous testing.

The company’s approach is to deliver flight-proven propulsion systems faster and more affordably. They claim to save customers an average of five years and $50 million compared to developing propulsion in-house. This efficiency is largely attributed to their vertically integrated model, where design, manufacturing, and testing are co-located at their 90-acre headquarters in Berthoud, Colorado. This allows for unmatched development time and rapid iteration. Additionally, their Advanced Manufacturing Lab in Youngstown, Ohio, specializes in 3D printing proprietary copper alloys, enabling rapid prototyping and scalable production.

Ursa Major was the first American company to successfully hotfire an oxygen-rich staged combustion engine – a complex and high-performing engine cycle previously mastered primarily by Russian manufacturers. This achievement underscored their technical prowess and commitment to pushing the boundaries of propulsion technology.

The Engine Lineup: Driving Diverse Missions

Ursa Major offers a family of liquid rocket engines and has expanded into solid rocket motors and in-space propulsion systems, each designed for specific applications and performance characteristics.

Liquid Rocket Engines:

Hadley: This is Ursa Major’s foundational engine, America’s first oxygen-rich staged combustion engine. It’s a 5,000-pound-force (lbf) thrust engine (6,500 lbf in vacuum variant) that uses liquid oxygen (LOx) and kerosene propellants. Hadley is designed to be reusable and versatile, suitable for small launch vehicles, orbital maneuvering, and critically, hypersonic applications. It features active throttle control and a wide throttle range, allowing for precise mission profiles. Hadley achieved its first successful flight in March 2024 and has since powered multiple successful missions for partners like Stratolaunch’s Talon-A hypersonic testbed, demonstrating sustained Mach 5+ flight and vehicle recovery. As of June 2025, Ursa Major secured a $32.9 million contract to deliver 16 upgraded Hadley H13 engines to Stratolaunch through 2032, further cementing its role in U.S. hypersonic test infrastructure.

Ripley: This engine offers significantly more thrust than Hadley, at 50,000 lbf (sea level) using LOx and kerosene. Also an oxygen-rich staged combustion engine, Ripley is positioned for small to medium commercial launch vehicles. Its high performance aims to provide a reliable and cost-effective solution for a variety of orbital insertion missions.

Draper: Introduced in May 2023, the Draper engine is a flexible liquid engine with the unique characteristic of storability similar to a solid motor, yet retaining the active throttle control and extended range of a liquid system. It uses hydrogen peroxide and kerosene propellants and provides 4,000 lbf of thrust at sea level. Draper is specifically designed for tactical hypersonics, missile defense, and in-space propulsion. Its ability to be stored for long durations and its rapid readiness make it highly valuable for defense applications where immediate response is critical. In May 2025, Ursa Major was awarded a $28.6 million contract by the U.S. Air Force Research Laboratory (AFRL) for responsive space, hypersonic, and on-orbit propulsion, specifically for the Draper system, including funding for its maiden flight test expected by the end of 2025. This contract positions Ursa Major as a lead integrator for a tactical flight demonstrator.

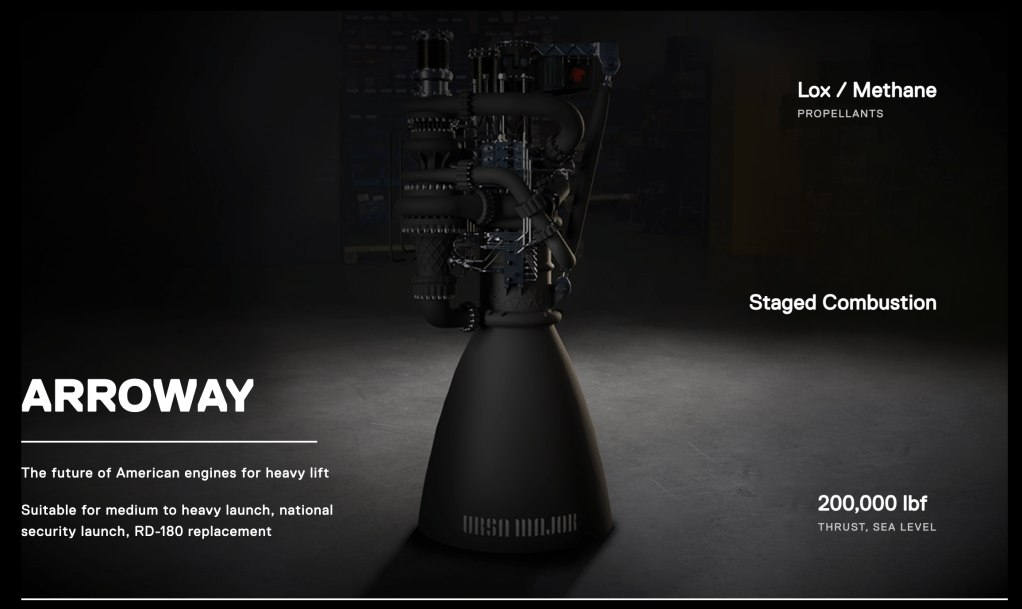

Arroway: Currently in development, Arroway is a larger engine designed for medium to heavy lift applications, including national security launches and as a potential replacement for foreign-sourced engines like the RD-180. It’s a 200,000 lbf (sea level) engine utilizing liquid oxygen and methane (LOx/Methane) as propellants, indicative of the industry trend towards more sustainable and efficient propellants. Arroway aims to provide high performance for next-generation launch vehicles.

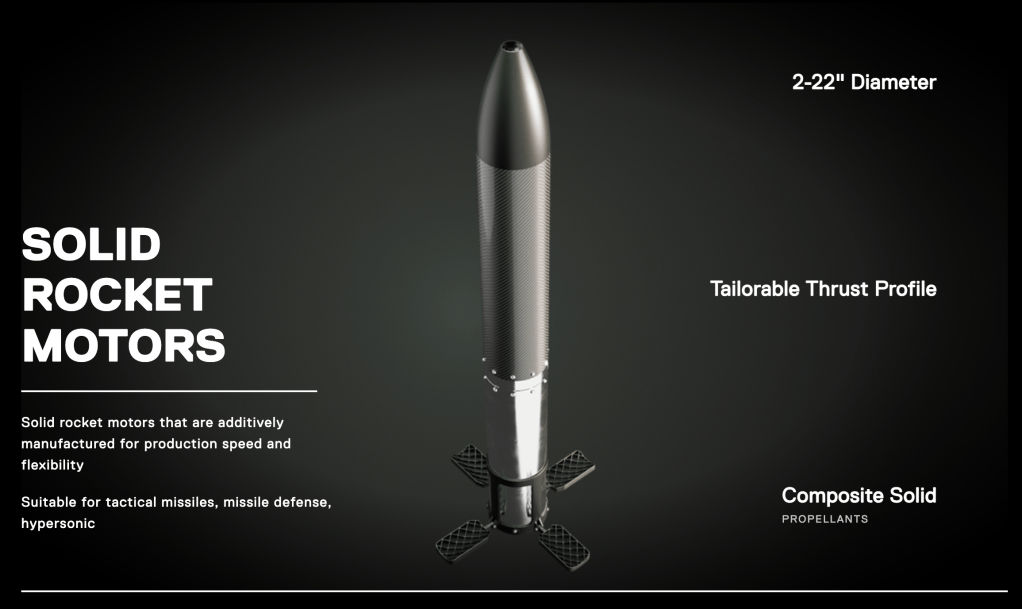

Solid Rocket Motors (SRMs): Recognizing a critical supply chain constraint in the U.S. defense industrial base for SRMs, Ursa Major has rapidly expanded its capabilities in this area. Their approach leverages additive manufacturing for rapid production and flexibility. They design SRMs in various diameters (from 2 to 22 inches) with tailorable thrust profiles. This modular production capability, using 3D printers, allows for quick adaptation to different casing sizes and rapid scaling of production to meet surge demands for tactical missiles and missile defense systems. In December 2024, Ursa Major successfully conducted a solid rocket motor flight test with RTX, demonstrating the real-world application of their SRM technology.

In-Space Propulsion: Ursa Major is also developing modular, hydrazine-based in-space propulsion systems designed for satellite maneuverability. These systems aim to provide customized degrees of freedom for satellite control, enabling reliable launch and in-orbit operations for various missions from Low Earth Orbit (LEO) to Geostationary Orbit (GEO) and beyond. They are developing critical components like propellant tanks, avionics, and thrusters in-house to optimize for performance, mass, and lead time.

Strategic Importance for Defense and National Security

Ursa Major’s business model and product portfolio are directly aligned with pressing national security needs. The U.S. Department of Defense (DoD) and its allies face challenges in securing reliable, high-performance propulsion systems for next-generation capabilities, particularly in hypersonics and responsive space.

- Hypersonic Advantage: The development and rapid production of engines like Hadley and Draper are crucial for accelerating the U.S.’s hypersonic capabilities. These engines provide the sustained power, maneuverability, and reusability needed for advanced hypersonic testbeds and future weapons systems, helping to deter evolving adversarial threats.

- Strengthening the Industrial Base: By offering propulsion as a product rather than a bespoke, in-house development, Ursa Major helps to diversify the defense industrial base and reduce reliance on a limited number of suppliers or foreign sources. Their additive manufacturing capabilities enable surge production, addressing supply chain bottlenecks for critical components like solid rocket motors.

- Responsive Space: For national security launches and in-space mobility, Ursa Major’s engines contribute to a more resilient and flexible space architecture. Their ability to deliver engines rapidly helps shorten timelines for deploying critical satellite capabilities.

- Cost Efficiency: By streamlining manufacturing processes and leveraging additive manufacturing, Ursa Major aims to provide high-performance solutions at a lower cost, freeing up defense budgets for other critical investments.

Funding and Growth

Ursa Major has attracted significant investment, underscoring investor confidence in its disruptive business model and technological prowess. The company has raised over $284 million in funding from a diverse group of investors, including BlackRock, Eclipse Ventures, Space Capital, RTX Ventures, and the Department of Defense’s Office of Strategic Capital (OSC). Notable rounds include an $85 million Series C in December 2021 and a $100 million Series D in April 2023, followed by a $38 million Series D in November 2023, and a $12.5 million grant from the DoD in September 2024.

With approximately 270 employees as of 2023, Ursa Major is rapidly scaling its operations. The company is actively recruiting top engineers and manufacturing talent, a reflection of its aggressive growth strategy and increasing demand for its products.

Leadership and Vision

The company is led by Dan Jablonsky (CEO), who took the helm in August 2024, succeeding founder Joe Laurienti. Jablonsky brings experience in rapidly scaling technology companies, reinforcing Ursa Major’s focus on operational execution and market leadership. Joe Laurienti continues to play a vital role in the company’s strategic direction. The team’s collective expertise spans propulsion engineering, advanced manufacturing, and strategic defense initiatives.

Ursa Major’s values—Cohesion, Conviction, and Humility—guide their operations, emphasizing teamwork, problem-solving, and continuous improvement. They are “busy doing,” constantly pushing the boundaries of what’s possible in propulsion.

The Road Ahead

Ursa Major is at the forefront of a paradigm shift in the aerospace and defense industry. By specializing in propulsion and leveraging advanced manufacturing, they are providing a crucial capability that enables faster development cycles and more robust supply chains for their customers. As the demand for launch services, hypersonic platforms, and advanced space capabilities continues to surge, Ursa Major’s role as an independent, high-volume producer of cutting-edge rocket engines and solid rocket motors will become increasingly vital. Their story is a compelling narrative of innovation, strategic foresight, and a profound commitment to powering the next generation of American and allied defense capabilities.